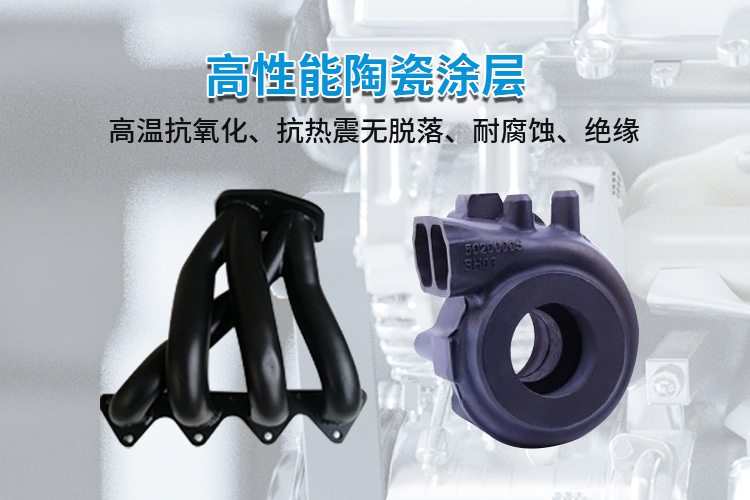

The main fans used for Suzhou ceramic coating are fans, pulverizers, blowers, etc. Induced draft fan and powder feeder are one of the main auxiliaries in power plant. Their wear and tear seriously affects the output of the unit, so they are frequently overhauled and maintained. It has become one of the hidden dangers in the safe operation of boilers in thermal power plants. For many years, although many surface strengthening methods, including heat spray welding of hardfacing and wear-resistant materials, surface coating of various polymer coatings, surface quenching and other effects are not ideal. The adhesive strength, adhesive wear resistance and wear resistance of wear-resistant adhesive are mainly used for wear-resistant materials. The wear-resistant ceramic material is applied to the wear-resistant performance of fan impeller. The technology has been applied in dozens of fan impellers. The longest service life has been more than 3 years, and good economic benefits have been achieved.

the main fans used for Suzhou ceramic coating are fans, pulverizers, blowers, etc. Induced draft fan and powder feeder are one of the main auxiliaries in power plant. Their wear and tear seriously affects the output of the unit, so they are frequently overhauled and maintained. It has become one of the hidden dangers in the safe operation of boilers in thermal power plants. For many years, although many methods of surface strengthening, including the effect of heat spray welding of hardfacing and wear-resistant materials, surface coating of various polymer coatings, surface quenching and so on, the effect is not very ideal. The adhesive strength, adhesive wear resistance and wear resistance of wear-resistant adhesive are mainly used for wear-resistant materials. The wear-resistant ceramic material is applied to the wear-resistant performance of fan impeller. This technology has been applied to dozens of blowers. The impeller has been used for more than 3 years and has achieved good economic benefits.

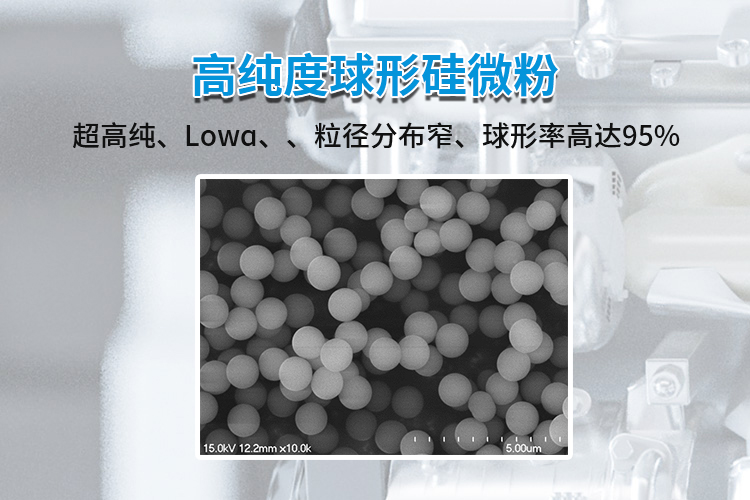

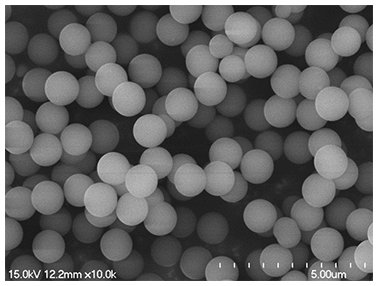

Feasibility of applying wear-resistant ceramic sheet to fan impeller. First of all, we must ensure that Suzhou ceramic coating has excellent wear resistance. Secondly, there are good bonding properties between ceramic and metal matrix, that is, the binder has good bonding strength and high temperature toughness. In the use of fan impeller, cold pressed sintered alumina ceramic is used. As a result, the hardness can reach more than hra88, at least 5 times. The wear resistance of high chromium cast iron is 10 times. The ordinary spray welding process can make the wear resistance meet the general requirements of fan service life. Due to the excellent wear resistance of ceramics, the thickness of ordinary ceramic plate is only 1.5mm. The actual operation of dozens of wind turbine impellers shows that sticking ceramics is an effective measure of wear resistance. As long as the construction is rigorous and the process is strictly followed, the ceramic pieces will not fall off. Because of the particularity of the fan impeller, the successful application in the fan impeller also provides a reference value for the application of other components, and provides a reference basis for the thermal power plant. Another effective anti-wear and anti-wear measure.

official account

official account