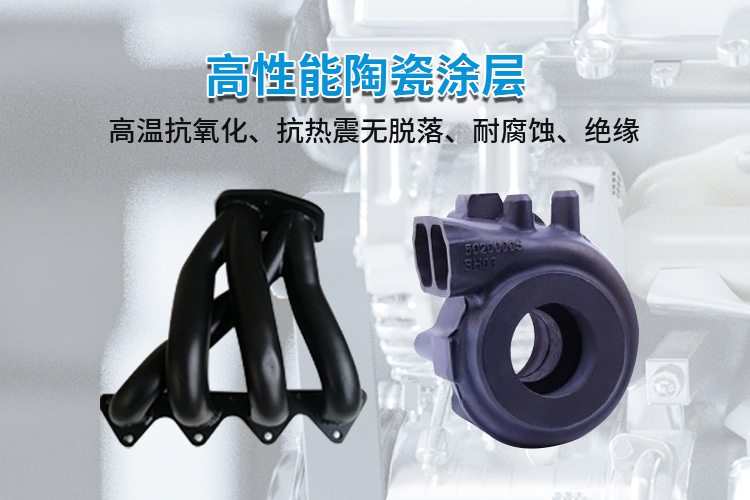

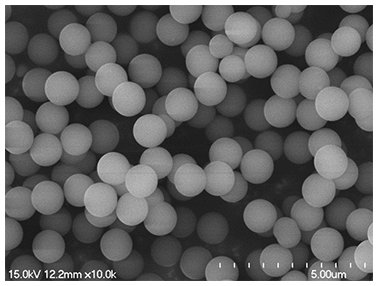

Suzhou ceramic coating is a kind of inorganic coating with high temperature resistance and wear resistance, that is, coating wear-resistant ceramic coating on the surface of common metal or non-metal materials can improve the performance of raw materials. The comprehensive properties of the raw materials have been greatly improved, and the wear-resistant ceramic coating is very popular. It is widely used in petroleum, metallurgy, aerospace and other fields. Industrial area. At the same time, this kind of material can save energy, because it can improve the service life of the material, and can increase the appearance by one or two times, so that the same material can be used for a long time, and reduce the loss and waste of the material.

Wear mechanism of Suzhou ceramic coating

when the wear-resistant ceramic coating moves relative to the surface of the component, the force acting on the wear-resistant ceramic coating can be decomposed into the force perpendicular to and parallel to the surface of the component.

1. The force perpendicular to the surface makes the abrasive embedded in the surface. There are a lot of indentations on the surface of plastic materials. After repeated actions, it can lead to fatigue and failure. For brittle materials, brittle failure occurs on the surface without deformation.

2. The force parallel to the surface causes the abrasive to produce tangential movement, which makes the surface engraved, cut and leave grooves. Cutting plastic materials and wear-resistant ceramic coating will cut chips on the friction surface.

for brittle materials, a large amount of debris is cut from the surface by cutting abrasive. Wear resistant Suzhou ceramic coating with high wear rate is the main damage form of many mechanical equipment.

official account

official account