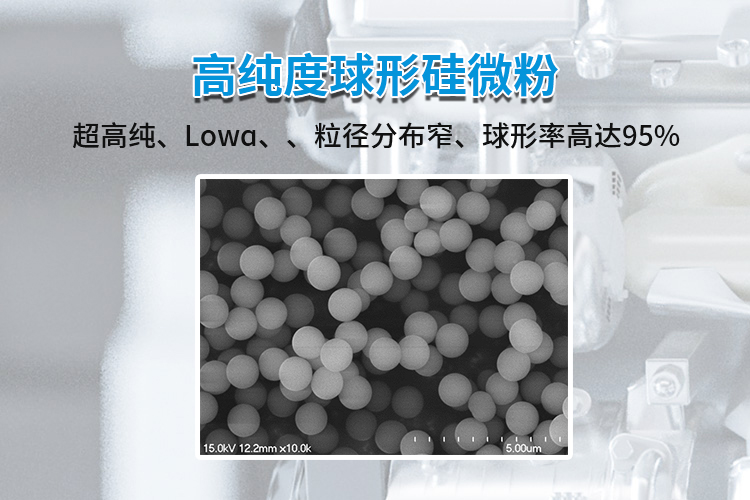

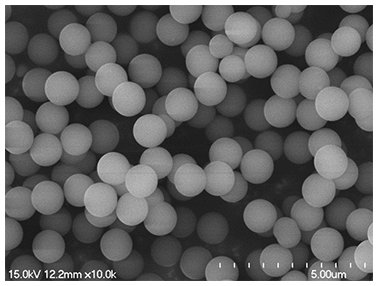

The relationship between coating thickness and coating process of Suzhou ceramic coating, the difference between abrasive particles with different thickness and large abrasive particles, rubber particles with different sizes, is that rubber particles with different wear resistance and nano ceramic particles can be divided into small particles and large particles wear-resistant rubber particles model. 0.5mm-1.5mm between the particle sizes of the abrasive particles. The size of the large abrasive particle glue is 1.0mm-2.5mm. There are some differences in the practical application of large particles:

As a wear-resistant epoxy repair agent, nano ceramic particles with high concentration are suitable to resist the wear of particles with diameter less than 3mm. It contains hard nano ceramic particles, which is a kind of epoxy repair material with hard wear-resistant point and strong wear resistance. Suitable for wear resistance of particles larger than 3mm diameter. The size and size of abrasive wear adhesive have little difference.

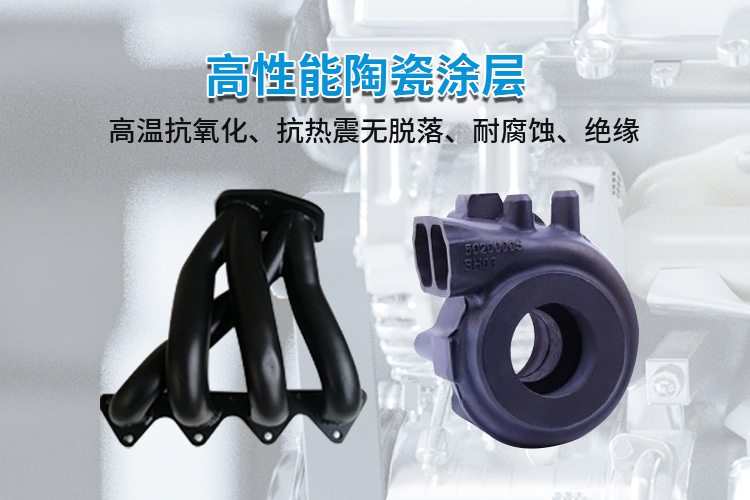

properties of Suzhou ceramic coating with large particles:

One or two-component special modified epoxy resin filled with high-performance wear-resistant ceramic balls.

2. Good thixotropy and operability, suitable for facade and complex surface construction.

Wear resistance and impact resistance.

fourth, Suzhou ceramic coating is suitable for the repair and protection of high load, large particle corrosion and repair equipment, such as the wear-resistant repair and preventive construction of elbow, cyclone separator, centrifuge, mud pump, etc. of ore dressing system in mines and metallurgical plants.

official account

official account