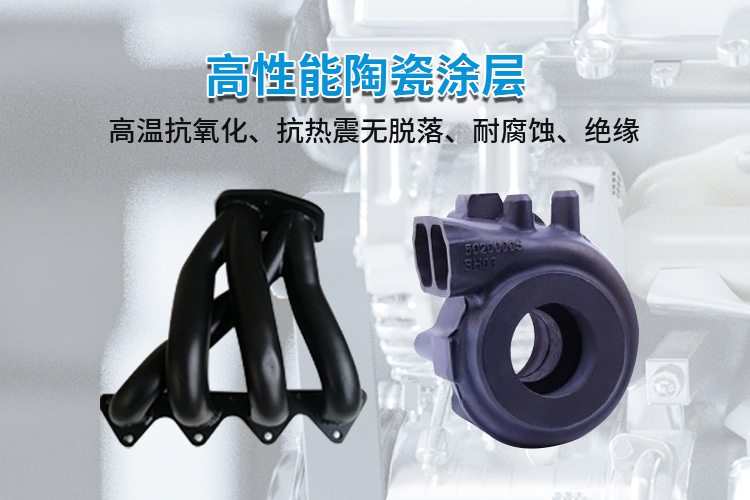

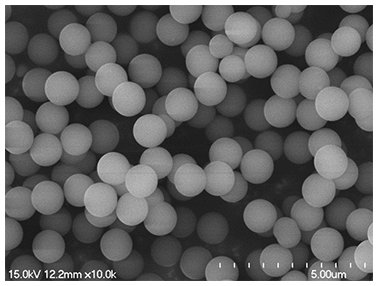

Suzhou ceramic coating for chimney is a kind of non-metallic cementitious material. The powder ceramic material of acid and alkali resistant synthetic raw material is made by strict process proportion and inorganic polymerization technology. At the construction site, special liquid and inorganic glue are added to the materials, and they are applied to the lining or surface of the equipment manually or mechanically through a series of chemical reactions. The combination strength and hardness of ceramics can be achieved after 3 days at room temperature, which is called the chimney wear-resistant ceramic coating.

wear resistant Suzhou ceramic coating is mainly composed of wear-resistant aggregate and bonding system, with a very large density and 130 MPa strength without macro defects, which is incomparable to ordinary concrete castables, and is the main part of synthetic compounds and ionic covalent compounds. The ionic bond is firm, so the strength and rigidity are large, which can effectively resist the influence and shear stress of materials. The comprehensive reinforcement measures and special treatment are combined to form a chemical combination to achieve high strength.

In view of the double strengthening measures of the wear-resistant Suzhou ceramic coating for chimney, some measures have been taken to effectively improve the material properties. In addition, the low expansion coefficient of ceramic material makes the volume stable and it is impossible to produce cracks, so its integrity is good. The whole construction has no joints and the integrity has been further improved. Due to the acid resistance and corrosion resistance, the synthetic raw materials will not react with the slag. At the same time, because the material is mainly high temperature synthesis raw material, the crystal is developed and the structure is complete. The ambient temperature will not have a great impact on the environment. It belongs to environmental inert substance and has poor environmental sensitivity.

official account

official account